Maintenance Best Practices for Hand-held Plasma Cutting Systems

By Tim Taylor, district manager, Victor Technologies

The THERMAL DYNAMICS® TRUE™ Series of CUTMASTER hand-held plasma

cutting systems take true cutting power, portability, multi-voltage

flexibility and “field-proven” protection to new levels. However, that

doesn’t give owners a pass on taking care of their equipment.

A plasma cutter needs clean air and electricity to operate. A good maintenance routine checks these points, ensures the machine functions as intended and does it on a set schedule. Below is a maintenance schedule that will help ensure your plasma cutter operates at peak output for years to come. Note that in extreme environments, especially those with dust, dirt and moisture, you should increase inspection frequency.

DAILY OPERATION CHECKS (or every six hours of use)

Primary power. Set the voltage selector controls, jumpers and similar components to match primary power voltage and phase before turning on the power. Don’t assume the last operator left everything in proper order. Note that CUTMASTER multi-voltage models have a convenient “Hi-Lo” switch on the back of the unit (see Fig. 1).

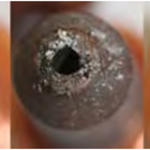

Air/gas source. Purge the compressed air or gas line to remove

moisture that might have built up overnight. Torch tip. Check the torch

tip and replace as required. Worn orifices become oblong, irregular and

pitted, all of which hinder the ability to cut without excessive dross

and maintain a precise, narrow kerf for accuracy. Shown in Fig. 2 (L-R):

a new tip, a used tip with some life remaining and a worn tip that

should be discarded.

Electrodes. Electrode tips contains a special element (hafnium) that

promotes arc starts. Each arc start consumes a minute amount of this

element. Replace the electrode when worn more than 1/16th of an inch, as

shown in Fig. 3.

Proper Reassembly. CUTMASTER torches are simply to reassemble because

they only have four components, as shown in Fig. 4 (L-R): torch,

cutting tip, electrode, start cartridge and shield cup.

Assembly Guidelines. The side of every CUTMASTER case features visual

diagrams and troubleshooting help (see Fig. 5). Note that most problems

with plasma cutters aren’t really problems. They’re simply torch

consumables that are worn or re-assembled improperly.

WEEKLY (or every 30 hours of cutting)

Start cartridge. Test the springs (shown in Fig. 6) and replace the

start cartridge if the spring seems weak, as worn springs lead to poor

arc starts. Torch. Inspect the torch for cracks or exposed wires, and

check the shield cup for spatter. Repair or replace as required. Fan.

Check the cooling fan for proper operation and unobstructed airflow;

vacuum or blow out the fan as needed.

Cables and hoses. Check cables and hoses for cracks and leaks. If

worn or damaged (see Fig. 7), discard and replace them. Do not attempt

to repair them, as this may create a safety hazard, especially with

cables carrying cutting power.

Check air pressure. Too little or too much pressure (refer to the

operator’s manual for proper settings) hinders performance and reduces

consumable life. Note that the CUTMASTER uses troubleshooting LEDs (Fig.

8) to indicate air pressure faults, which helps diagnose problems.

EVERY THREE MONTHS

Parts. Replace all broken parts. Torches are meant to last a long

time—that’s why CUTMASTER torches have a one-year warranty—but don’t use

the shield cup as a chipping hammer. The cup is sturdy, but the torch

has electrical connections inside of it. Also, just finger-tighten the

shield cup, as over-tightening can create a false cup-related fault (see

Fig. 9, which shows the limit switch for the “Parts in Place” fault).

Clean. Clean the exterior of the power supply.

EVERY SIX MONTHS (or 720 hours of cutting)

Filters. Check the internal air filter (see Fig. 10) and clean or

replace as required. If moisture or oil, such as from reciprocating air

compressors, seeps into the air system, it can cause problems with arc

starts, create an intermittent “sputtering” arc and premature electrode

wear (look for burn marks that swirl up the electrode). For air supplies

without a filter/dryer, install an external in-line air filter to

support the cutter’s internal filter (see Fig. 11).

Work or ground clamps. Use a good, strong clamp and check the

cable-to-clamp connection (see Fig. 12). Loose connections can really

affect cutting current, and they’re often overlooked. Also, be sure to

clamp to clean, bare metal and clamp as near to the work piece as

possible. Poor grounding causes a huge amount of problems that people

incorrectly blame on the plasma cutter.

Remove built-up debris. Remove the machine covers, vacuum out debris and use shop air to blow out dust. Pay attention to the spaces cooling fins (see Fig. 13), which can trap debris.

Contactor points. Check all contactors and electrical connections for signs of severe arcing or pits, replacing components as necessary. Clean and blow off with shop air as needed.

Note that metal grinding dust can affect electronic components and lead to short circuits. To minimize their impact, angle grinders to direct sparks away from the machine.

CUTMASTER plasma cutters set the standard for durability, but sooner or later any machine will fail with neglect. Take a few minutes to check the plasma cutter at the start of each day, stick to the maintenance routine outlined in the operator’s manual* and chances are your CUTMASTER will never see a repair tech’s workbench.