Successfully switching from acetylene to fuel gases such as propane and propylene requires a modest equipment change and learning a few new techniques.

By John Henderson, senior product manager, ESAB

Due to supply chain issues with acetylene during the spring of 2011, industries using oxy-fuel have explored using alternative fuels for their heating and cutting requirements. Common alternative fuels include propylene, propane and natural gas, as well as proprietary gas blends.

Over the years, an unfortunate number of misconceptions and myths arose surrounding alternative fuels. This article sets some of the facts straight and provides hand-held torch operators with the most critical information: how to select the right equipment and how to use the right techniques to successfully cut and heat with alternative fuels.

Fuel Characteristics

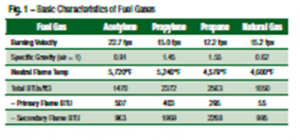

Without going into too many technical details, there are some important differences in the fuel gases (see Fig. 1).

First, alternative fuels have a tendency to “float” up or down. Natural gas is lighter than air, while propane and propylene are heavier. Acetylene is very close to that of air, so it won’t float as much. Because of these differences, operators need to learn different techniques for lighting a torch using alternative fuels.

Second, different gases have different burning rates at which the gas burns back toward the torch tip (while a flame may look as if it’s burning away from the torch, the opposite is actually happening). Alternative fuels have slower rates than acetylene. Achieving proper flame attachment, or the standoff between the end of the tip and ignition point of the flame, requires using tips specifically engineered to accommodate the particular burning rate of the fuel gas.

Third are the heating characteristics of the gases. Acetylene releases a majority of its heat (BTUs) in the primary flame, which is why acetylene has a concentrated heat output. Alternative fuels release more of their heat in the secondary flame and create more of a “soaking” or “quenching” type heat. As an example, when heating a large plate with alternative fuels, you can easily heat the whole plate cherry red. With acetylene, the starting point will have darkened by the time the torch reaches the end of the plate.

Common Misconceptions

One big misconception is that alternative fuels can’t be used for welding steel because the flame is not hot enough. Considering carbon steel alloys melt between 2,500 – 2,800°F, this is quite inaccurate. The real reason is that alternative fuels don’t create any shielding gas. Conversely, a proper mixture of oxygen and acetylene with a neutral flame produces CO2, which in turn shields the molten weld puddle from atmospheric contamination. Realistically speaking, this is not much of a drawback, as most industries have substituted other processes for oxy-fuel welding.

Another misconception is that because alternative fuels are not quite as hot, they don’t cut as well. When cutting, the oxygen stream does the real work. After all, oxy-fuel cutting is nothing more than high-speed oxidation, or the common rusting of steel. All of the commercially available fuel gases have a high enough flame temperature to achieve the desired results when using the correct equipment and proper techniques.

Equipment Considerations

The core elements of a cutting system are the regulator, the hose, the torch and the cutting tips.

Regulator. The safety standard ANSI Z49.1-2005 Safety in Welding, Cutting and Allied Processes clearly states that, “Pressure reducing regulators shall be used only for the gas and pressures for which they are labeled.” A regulator for use with propane or propylene must be marked “L.P. Gas” to indicate that it can be used with liquefied petroleum fuel gases (see Fig. 2). Victor® EDGE™ series models are color-coded and labeled for easy identification; use orange for L.P. and green for oxygen. High capacity choices for propylene, propane and natural gas include the ESS4-40-510LP and ESS4-125-510LP, while medium capacity EDGE regulators include the ESS3-40- 510LP and ESS3-125-510LP. Be sure to select a regulator with a “510” CGA (Compressed Gas Association) connection and sufficient delivery pressure for the application. While alternative fuels are safer to use because they do not have the delivery pressure, withdraw rate and storage issues associated with acetylene, Victor still recommends consulting with a welding supply distributor when switching to a new fuel gas.

Hose. CGA and RMA (Rubber Manufacturers Association) recommend a Grade T hose (Fig. 3) for alternative fuels. The neoprene liner of this hose will not allow the liquid phase of an alternative fuel to permeate through it. Grade R and RM hose (the grades sometimes used for acetylene) can potentially allow liquefied gas to permeate through the gas hose and into the oxygen hose.

Torch. Torches mix fuel gas and oxygen using different technologies. Those with a “spiral” or “equal pressure” mixer are calibrated to work with both lower-pressure fuels (Alternative) and higher-pressure fuels (Acetylene). These torches keep the gas pressurized and mix them via turbulence between the handle and the torch head (Fig. 4). There is no need to change equipment when switching to alternative fuels when using torches of this design.

Some other torches feature an “injector” or “venturi” style mixer that does not pressurize the fuel gas; the oxygen actually “siphons” the fuel out at the mixing point. These torches are best used for work at 2 psi and below, a rare occasion.

Victor torches feature a Universal Gas Mixer that combines the spiral and injector principles. The result is a high performance torch that operates on any fuel gas delivered at 2 psi and above.

Tips. As noted earlier, fuel gases burn at different velocities. Manufacturers such as Victor engineer consumables to match the characteristics of each fuel gas. Specifically, the slower burning rate of alternative fuels requires using a recessed tip to create more space for proper flame attachment (Fig. 5). Alternative fuel tips with a two-piece design provide the best performance. The burning rate of acetylene creates a natural standoff, so acetylene tips are flat and manufactured as a single piece.

Lighting Procedure

As noted, alternative fuels have a tendency to float, so operators should learn three methods of lighting a torch—one will definitely work. In all cases, when using a standard combination torch, first open oxygen valve on the handle all the way (Fig. 6) and adjust the flame from the oxygen valve on the cutting attachment. This ensures maximum oxygen flow to the cutting lever. (Fig. 7)

In addition to different lighting procedures, alternative fuels require a different shut off procedure: always shut off the oxygen first, alternative fuel gas last. Note that all other standard safety procedures, especially those for personal protective equipment, apply to alternative fuel gases.

Achieving a Neutral Flame

Alternative fuels require a different technique to achieve a neutral flame. Acetylene requires increasing gas flow to the point where soot discharge disappears (or when the flame achieves a small standoff from the tip) and then adding oxygen until the secondary flames recede to the point where they are even with the primary flames, or the “luminous cones” at the tip.

With alternative fuels, the flame needs to be “walked up” or “forced” to prevent starving or extinguishing the flame.

After lighting the torch and adding the initial preheat oxygen, alternately add more fuel and more oxygen (Fig. 8) by opening the respective valves ¼ to ½ turn at a time until the fuel gas valve is completely (or almost completely) open. Then add oxygen until the flame creates a loud whistling sound (view video) and the primary cones reach their shortest point (Fig. 9). Depress the cutting oxygen lever and readjust the preheat oxygen if necessary. Note that with propylene, adding a small additional amount of preheat oxygen will produce a more concentrated flame with a heat pattern similar to acetylene.

To check for a neutral flame, place the torch perpendicular to and near the surface of the work piece. The preheat flames will create a star pattern with clearly defined legs about 2 – 3 inches long (Fig. 10). An oxidizing flame will have shorter and sharper legs, where a carburizing flame has longer and more feathery legs. Also, properly set neutral flames look distinctly different with different fuel gases (Fig. 11).

Cutting Tips & Techniques

When using alternative fuels, common troubles can be addressed simply by using different cutting tips. For example, some people say that preheat times are too long. In this instance, replace the General Purpose (GP*) tip with a Heavier Preheat (HP*) tip. With

Victor, GP tips have 18 preheat slots versus HP tips that have 22 slots. The four additional slots allow HP tips to apply more heat to the contact area, enabling alternative fuels to nearly match the preheat time of acetylene. In addition, HP tips make lighting of the fuel gas easier, which can help when working outdoors or in windy areas. When working with high alloy plate, extremely rusty plate or when beveling, HP tips can also improve performance. Note that Victor offers these heavier preheat tips for both propylene (model “HPP”) and natural gas/propane (HPN). Cutting tip sizes are identical for those used with acetylene. Victor also offers alternative fuel tips for gouging, rivet washing and cutting close to bulkheads.

Heating Nozzles

Just as with cutting, heating with alternative fuels requires different nozzles to accommodate their burning rates, and they use the same lighting techniques noted above. For those currently using a Victor MFA (multi-flame attachment) heating head, the best Victor replacement product is the Type 55 multi-flame heating nozzle.

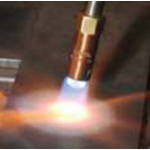

When working with alternative fuels, remember that they have a more soaking type heat that heats a larger area faster (Fig. 12) compared to acetylene.

For alternative fuel applications that require concentrated heating, Victor offers the Concentrated Heat Tip (CHT) adapter. This adapter transforms a standard HPP or HPN cutting tip (size 5 is good for most applications) into a heating tip by enabling mixed gases to flow through all orifices and by transforming the center cutting stream into a concentrated heating stream.

Summary

When switching from acetylene to alternative fuels, switch to the appropriate regulator, a Grade T hose and cutting and heating tips designed to optimize performance with alternative fuels. There is no need to change the torch as long as it uses a “universal” or “spiral” type gas mixer and gas delivery is above 2 psi. Some alternative fuel tips have recommended pressure settings that are different from acetylene.

By following the guidelines in this article and viewing the associated video tutorial at https://vimeo.com/esabtraining, companies will be able to do everything with alternative fuels that they can do with acetylene. The only exception is welding.